Some applications include end mills, blades, broaches, form tools, taps, reamers, punches, thread roll dies, header tooling and milling cutters. As mentioned above, it does many of the same things as standard molybdenum HSS only better. M42 is a common choice for many typical HSS applications. What Are Common Applications for M42 Cobalt Steel? Therefore, it is not a good choice for applications that may involve grinding. However, the ease of grinding of M42 cobalt steel is lower than most alloys due to its hardness. Its red hardness is superior to M2, M3, M4, M7, PM M4, PM T15 and PM23. The wear resistance is greater than that of M2, M3, M7 and PM23. The following are the amounts of each key element in its chemical composition: Finally, the machineability is 35% to 40% that of carbon steel. The modulus of elasticity is 30 x 10 6 psi. M42 has a density of 0.282 pounds per cubic inch. It also costs less compared to tools made with carbide while being less likely to chip when used for interrupted cuts. Additionally, it can be used for longer without tool changes. It can take on higher cutting speeds than many other steels. It is one of Griggs Steel’s most popular alloys. It has become a go-to material for machining applications thanks to its extremely impressive performance. Otherwise, it is very similar to other molybdenum-series high speed steels. M42 is a specific HSS alloy including 8% cobalt. That means cost savings for industrial applications. Tools made with these alloys can be run longer with less maintenance. Shorter Cycles: The above characteristics add up to one very important practical benefit: shorter cycle times.With the improvements of cobalt steel, the advantages are only compounded.

These characteristics are the main reasons why people choose high speed steel. Heat and Abrasion Resistance: Similarly, high speed cobalt tends to perform very well in terms of heat and abrasion resistance.Notably, these alloys perform especially well at high heats, maintaining their hardness and usability in production environments. Superior Red Hardness: The addition of cobalt can bring the Rockwell hardness up to 70 Min.These are some of the key characteristics of these alloys: There are many great reasons to consider using a cobalt steel alloy. What Are the Benefits of High Speed Cobalt? These improved alloys (especially M42) add to the characteristics that users love about HSS and simply make them better. High speed steel alloys with cobalt are more modern alloys than molybdenum alloys.

Cobalt steel upgrade#

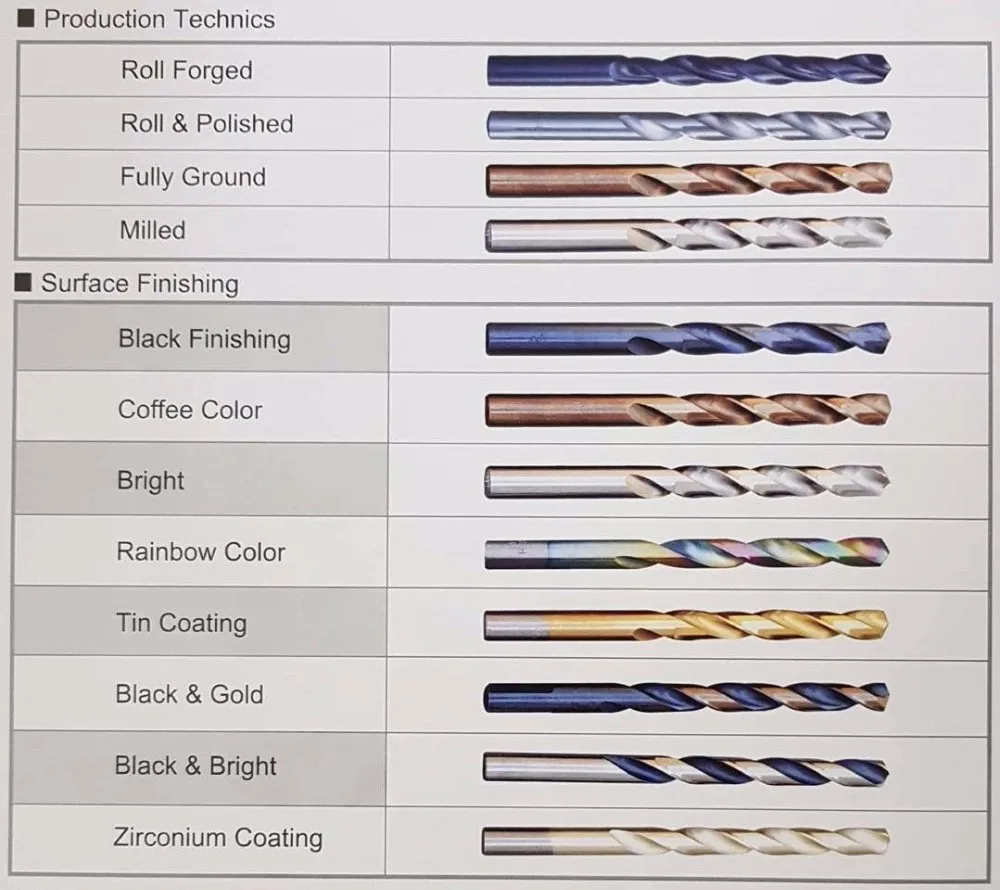

For many applications, high speed cobalt is a direct upgrade on other high speed steels. For example, M42 is similar to molybdenum high speed steel (another common type) but with an additional 8% cobalt. What Is Cobalt Steel?Īs the name suggests, these alloys include cobalt as a significant addition. High speed cobalt tends to have superior hardness and heat resistance compared to other HSS. Some HSS alloys are cobalt steels that have some helpful characteristics from using 5% to 8% cobalt. Now let’s jump into our picks for the most reliable and best drill bits for metal you can find out in the market right now.High speed steel is a valuable type of steel that is designed to withstand the temperatures and stresses of high-speed applications such as saw blades and drill bits. High-Speed Steel (HSS) is a lower-cost drill bit good for drilling into soft steels, wood and plastic.Ĭobalt (HSCO) includes between 5 and 8% cobalt in the base, making it an excellent option for drilling into harder steel and stainless steel.Ĭarbide is the strongest drill bit for metal and is typically reserved for professional-grade tools.īlack Oxide is a coating added to HSS drill bits that helps reduce friction and speed up drilling through hard metals.

Cobalt steel how to#

Here’s a crash course on how to choose the best drill bit for metal: And don’t forget to always use your metal drill bit at low speed for the best results. You can use one made of titanium for soft metal, and for light metal and aluminum, a black oxide coated-drill bit or a high-speed drill bit will do the job. Cobalt is a material that offers better results in drilling through metal successfully. How To Choose the Best Drill Bits for Metalįor the best power drilling results for metal and steel, always choose a drill bit made of or has a percentage of cobalt. Usually, these bits are an excellent choice for soft metals and aluminum, but hard metals still may need a specialized drill bit. Often these drill bits for metal are sold as kits and are multi-purpose bits that you can use for various types of materials, including metal, wood and plastic. There are many metal drill bit materials to choose from, including cobalt, high-speed steel, black oxide, titanium, etc.

0 kommentar(er)

0 kommentar(er)